Reverse Engineering Services

- Home

- Reverse Engineering Services

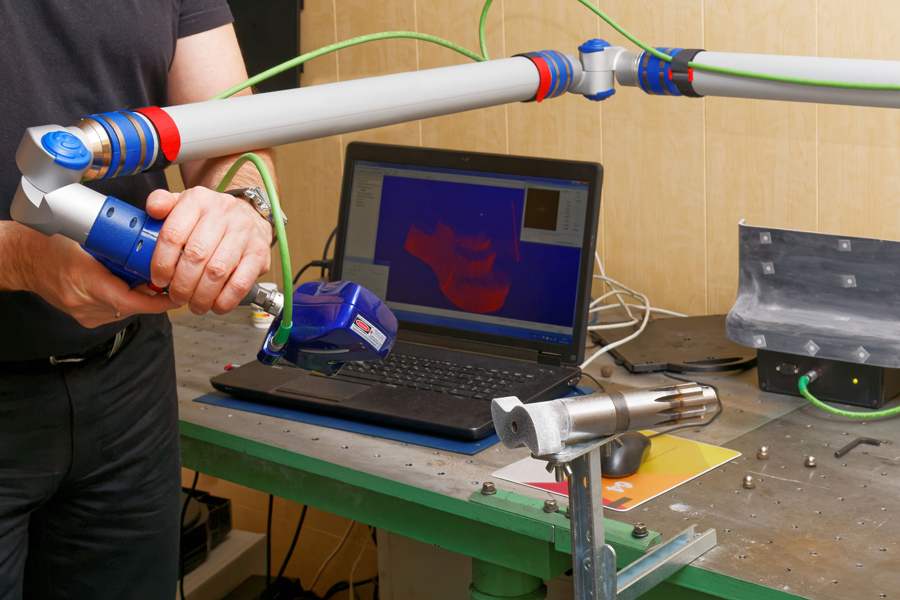

Reverse engineering can be used to recreate or reproduce a physical object by capturing its dimensions and geometry through 3D scanning techniques.

It is utilized to replicate the object, enhance and optimize existing designs, or systems to uncover its underlying principles and mechanisms.

Framing design to create an end product is engineering then practising a contrary approach is reverse engineering, manufacturers tend to approach reverse engineering to reconstruct an existing product in a better way or to create an updated product.

Implementing 3D technology further enhances the reverse engineering approach and helps manufacturers to visualize easily the hidden design behind the existing product and paves the way to create a fresh model or prototype with more efficacy.

3D Reverse Engineering helps to unleash and narrow down all the details of the prototype or end product by scanning the object and analyzing its minute physical components. These 3D scanning services have been very pivotal.

Some of the most common uses of Reverse Engineering

- Legacy Parts Replacement

- Resurrecting obsolete designs

- Parts Service or Repair

- Failure Analysis

- Parts Improvement

- Diagnostics and Problem-Solving

3D Scanning, Reverse Engineering, 3D Inspection & Manufacturing Services provider under One Roof.

Our dedicated team of experts are always available to help you for your needs.

Introduction to Reverse Engineering

Reverse engineering is a pivotal process in the realm of innovation and technology. It involves dissecting and analyzing a product or system to understand its design, functionality, and components. By unraveling the intricacies of existing products, reverse engineering enables companies to gain valuable insights, improve upon existing designs, and develop innovative solutions.

Importance of Reverse Engineering Services

Reverse engineering services play a crucial role across various industries, from automotive and aerospace to consumer electronics and manufacturing. They empower businesses to stay competitive by:

- Understanding competitors’ products: By reverse engineering competitors’ products, companies can gain insights into their strengths, weaknesses, and design strategies, allowing them to develop better offerings.

- Enhancing product design and development: Reverse engineering enables companies to analyze existing products, identify areas for improvement, and innovate upon them to create superior products.

- Legacy product restoration: Reverse engineering allows companies to recreate or modernize outdated or obsolete products by analyzing and replicating their design and functionality.

- Accelerating innovation: By reverse engineering complex systems or components, companies can expedite the innovation process, saving time and resources while developing new products or technologies.

RM Engineering Technologies’ Approach to Reverse Engineering Services in Chennai

At RM Engineering Technologies, we pride ourselves on our comprehensive and meticulous approach to reverse engineering. Our process involves:

- Initial consultation and assessment: We begin by understanding our clients’ specific needs, goals, and challenges to tailor our reverse engineering approach accordingly.

- Advanced scanning and imaging technology: We utilize state-of-the-art scanning and imaging technology to capture detailed data and measurements of the product or system under analysis.

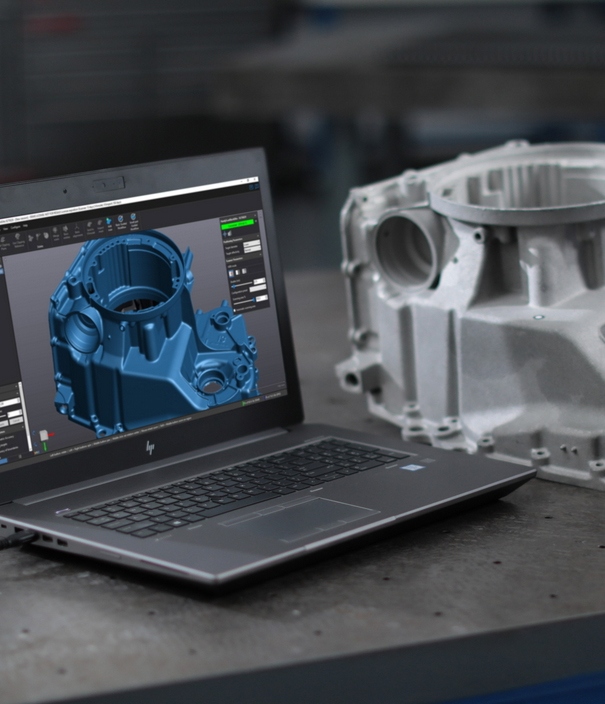

- Thorough analysis and reconstruction: Our team of experienced engineers meticulously analyze the collected data to understand the product’s design, functionality, and components. We then reconstruct digital models or prototypes based on our findings.

- Iterative refinement and validation: We collaborate closely with our clients throughout the reverse engineering process, incorporating feedback and making iterative refinements to ensure the accuracy and quality of the final deliverables.

Case Studies: Successful Applications of Reverse Engineering

Over the years, RM Engineering Technologies has successfully applied reverse engineering to a wide range of projects, including:

- Reverse engineering and redesign of automotive components to improve performance and efficiency.

- Reverse engineering of complex electronic devices to enhance functionality and usability.

- Replication of legacy industrial equipment to ensure uninterrupted production processes.

Benefits of Choosing RM Engineering Technologies for Reverse Engineering Services in Chennai

When you choose RM Engineering Technologies for your reverse engineering needs, you can expect:

- Exceptional expertise and experience: Our team comprises highly skilled engineers with extensive experience in reverse engineering across diverse industries.

- Cutting-edge technology and tools: We leverage the latest scanning, imaging, and modeling technology to deliver precise and accurate results.

- Tailored solutions: We work closely with our clients to understand their unique requirements and provide customized solutions that meet their specific needs and objectives.

- Timely delivery and cost-effective solutions: We are committed to delivering high-quality results within agreed-upon timelines and budget constraints.

Why Choose Reverse Engineering Services in Chennai from RM Engineering Technologies

Reverse engineering is a powerful tool for innovation and product development, and RM Engineering Technologies is your trusted partner for all your reverse engineering needs in Chennai. With our expertise, advanced technology, and commitment to excellence, we can help you unlock new possibilities, accelerate innovation, and achieve your business goals. Choose RM Engineering Technologies for unparalleled reverse engineering services that drive success and propel your business forward in Chennai.