3D scanning has become a game-changer for industries requiring precise measurements, reverse engineering, or quality inspections. Whether you’re working with intricate components or large-scale projects, choosing the right service provider ensures successful outcomes. To guide your selection, here are the critical factors to consider, along with real-world examples that highlight the value of effective 3D scanning services.

1. Accuracy and Precision

When accuracy is paramount, verify that the provider can meet your project’s tolerance levels. Industries like aerospace or healthcare require micron-level precision, while others may allow broader tolerances. An excellent provider ensures accurate data for seamless project execution.

2. Type of 3D Scanning Technology

Different projects demand different technologies, such as laser scanning for intricate details or structured light scanning for larger objects. Ensure the provider’s equipment matches your needs to avoid compromising quality.

Customer Review

“The team used cutting-edge laser scanners to inspect our components, capturing intricate details with exceptional precision. Their technology surpassed our expectations!”

3. Material Compatibility

Materials like reflective or transparent surfaces often require specialized handling during scanning. Ensure the service provider has the expertise to manage unique materials effectively.

Example

A client in the automotive sector required 3D scans of reflective engine components. By applying anti-reflective coatings, RM Engineering captured precise data without compromising surface details.

4. Turnaround Time

Time-sensitive projects demand quick and efficient service. Ask providers about their timelines and capacity to meet urgent deadlines. Providers with streamlined processes can minimize delays without sacrificing quality.

5. Experience and Industry Expertise

Providers with a strong track record in your sector can better address industry-specific challenges. Experience translates into efficient handling of unique requirements and a deep understanding of project goals.

6. Post-Processing Services

Scanning is only the first step—data often requires cleaning, stitching, or conversion to CAD models. Providers offering robust post-processing capabilities can save you the hassle of outsourcing these tasks elsewhere.

7. Customer Support and Communication

Strong communication ensures alignment between your expectations and the provider’s deliverables. Look for providers who are responsive, transparent, and willing to address your concerns promptly.

Customer Review

“RM Engineering’s team kept us informed throughout the entire project. Their attention to detail and willingness to adapt ensured we were completely satisfied with the results.”

8. Cost Efficiency

While affordability is important, overly low costs can signal compromises in quality or technology. Strike a balance by selecting providers that offer transparent pricing and a strong value proposition.

9. Reputation and Reviews

Research client testimonials, reviews, and case studies to evaluate the provider’s credibility. Positive feedback specific to your industry or project type is a good indicator of their reliability.

Customer Feedback

“The accuracy of their 3D scans and the efficiency of their process saved us significant time and resources. We highly recommend their services!”

10. Scalability for Future Needs

A provider capable of scaling their services ensures they can accommodate your growing requirements. This is particularly important for businesses anticipating expanded operations or increased project complexity.

11. Security and Confidentiality

Protecting your intellectual property is vital. Choose providers with robust security measures, including non-disclosure agreements (NDAs) and secure data handling protocols.

Real-World Applications

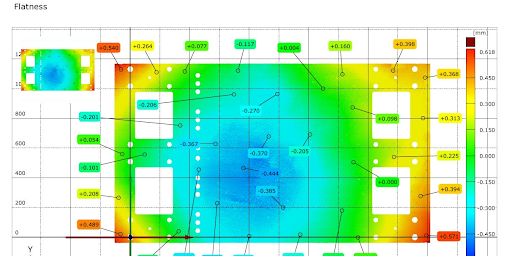

Flat Plate Fixture Inspection

RM Engineering conducted a detailed inspection of a flat plate fixture measuring 2130 x 1225 x 37 mm. By employing advanced 3D scanning techniques, the team captured high-resolution data points across the entire surface and internal structures, ensuring compliance with GD&T standards. The project showcased the team’s ability to handle large components efficiently without compromising accuracy.

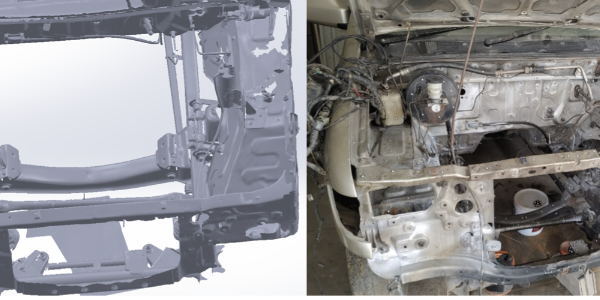

IC Engine to EV Conversion

In a groundbreaking project, RM Engineering converted an IC engine into an EV using 3D scanning and reverse engineering. The process involved digitizing engine components with unmatched accuracy and creating CAD models for seamless integration. Key metrics highlighted the high precision of the scans and the cost-effectiveness of the conversion, reinforcing RM Engineering’s innovative capabilities.

Conclusion

Selecting the right 3D scanning service requires careful evaluation of factors like accuracy, technology, material compatibility, and customer support. RM Engineering consistently delivers high-quality 3D scanning and reverse engineering services tailored to industry needs. With proven expertise and cutting-edge technology, RM Engineering is a leader in 3D scanning and reverse engineering services in Chennai.