Introduction

This case study explores how RM Engineering successfully converted an internal combustion (IC) engine to an electric vehicle (EV) using 3D scanning and reverse engineering services. The project showcases the innovative use of technology and the remarkable results achieved.

Project Overview

The project involved the conversion of an IC engine to an EV, a process that required detailed understanding and precise replication of the original engine components. RM Engineering utilized 3D scanning and reverse engineering services to achieve this.

Challenges

Discuss the challenges faced during the project. This could include understanding the complex structure of the IC engine, ensuring the accuracy of the 3D scans, and the intricacies involved in reverse engineering.

Solution

RM Engineering employed 3D scanning technology to digitize the IC engine components. The scans were then used as a reference to create 3D CAD models. The reverse engineering process involved hundreds of sketches and planes to accurately replicate the original components.

Results

Discuss the results achieved in this section. This could include the successful conversion of the IC engine to an EV, the accuracy of the 3D models compared to the original parts, and the efficiency of the reverse engineering process.

Key Metrics and KPIs

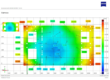

1. Accuracy of 3D Scans: Measure the accuracy of the 3D scans against the original parts. This can be done by comparing the scan data against the CAD model. For example, if everything colored green is within 0.5mm of the original part, this indicates a high level of accuracy.

2. Efficiency of Reverse Engineering Process: Evaluate the efficiency of the reverse engineering process. This can be measured by the number of sketches and planes needed to create the 3D CAD model, and the time taken to complete the process.

3. Performance of the Converted EV: Assess the performance of the converted EV. This could include metrics such as range, speed, and power output.

4. Cost-effectiveness: Evaluate the cost-effectiveness of the conversion process. This could be measured by comparing the cost of conversion against the cost of purchasing a new EV.

5. Customer Satisfaction: Measure customer satisfaction through surveys or feedback. This could include factors such as the performance of the converted EV, the accuracy of the 3D models, and the efficiency of the reverse engineering process.

Conclusion

Summarize the key findings of the case study. Highlight the success of the project, the effectiveness of the 3D scanning and reverse engineering services, and the benefits of the IC engine to EV conversion.